|

|

|||||||||||

|

Load is a Key Process Indicator in forging. Consistent press load means consistent product quality. By monitoring press load, variations in billet dimension, billet geometry, billet and die temperature, press speed, lubrication etc. may be detected. |

|||

|

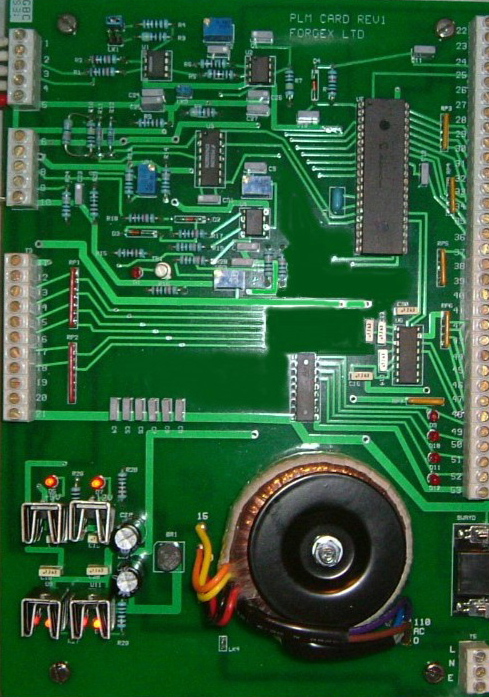

Press Load Monitors are easily retro-fitted to crank or screw presses. Our monitoring systems capture and display press load for each blow. In addition, other useful data may be collected. |

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

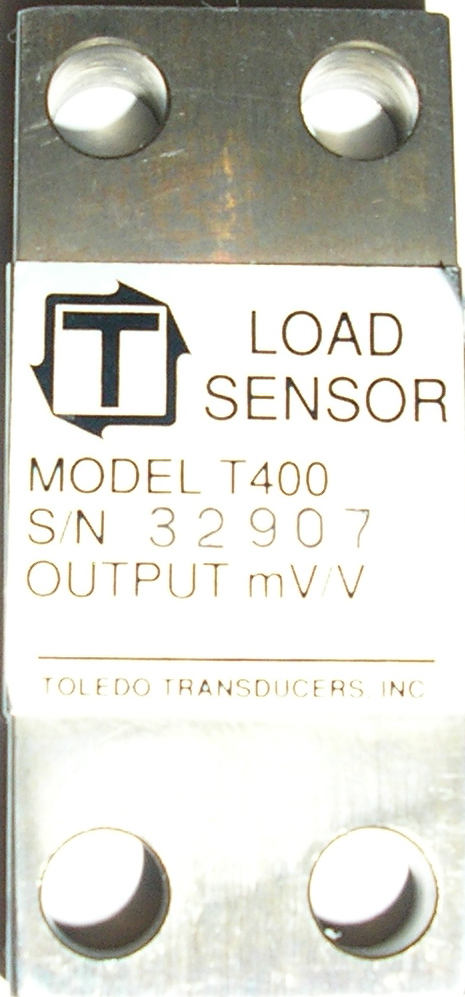

The press load monitor may be calibrated to read Tons, Tonne or % of press capacity. Our load cell has a capacity of 2500 Tonne and is trace-able to national standards. |

|

|

||||||||||||||||||||||